Craft Master Growlers perform at their best with proper maintenance and care. In the event you ever experience an issue with your pressurized growler’s regulator cap, the below list of troubleshooting tips to get your growler back into shape and ready for its next fill quickly and efficiently!

Do not submerge the CO2 regulator cap when cleaning, or use PBW or other chemicals.

Rinse cap thoroughly after use with cartridge holder off/detached. Dry standing upright. Keep cap off when growler not in use. Check from time to time that the bushing is secure.

Too much gas is released when installing a CO2 cartridge in the cap

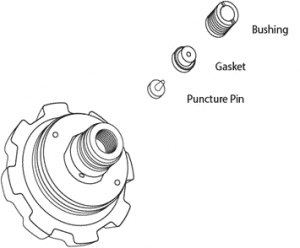

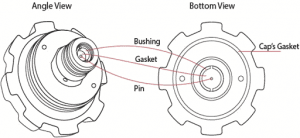

- The bushing holding the gasket and the puncture pin needs to be tightened.

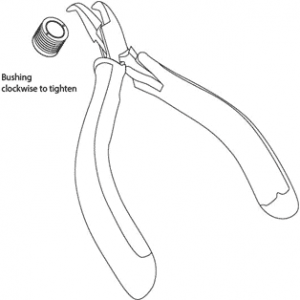

- Tighten down the bushing with a flat head screw driver or a pair of bent needle nose pliers.

Preventative Maintenance:

- Periodically inspect the bushing that holds down the gasket seal and the CO2 puncture pin. Tighten if necessary.

CO2 leaks out of the growler overnight

- The bushing holding the gasket and the puncture pin needs to be tightened.

- Tighten down the bushing with a flat head screw driver or a pair of bent needle nose pliers.

- Possible gasket fray or damage due to rush of CO2 gas

- Visually check if gasket is frayed or damaged (not smooth)

- If the gasket is damaged a slow leak is possible. Replace the gasket.

- The cap does not seal on the rim of the growler

- Inspect the flat silicone gasket in the cap. If it is damaged, replace it.

- The safety valve is worn or damaged

- The cap must be replaced

The Pressure gauge is not working properly or is “sticky”

- It’s very possible there is beverage residue blocking the airway

- Clean and clear the shaft with warm water and PBW solution

Preventative Maintenance:

- Clean the cap after each use and leave upright to dry.

The Pressure gauge is leaking or blowing off at pressures below 15 PSI

- The spring may be damaged or worn out

- The cap will need to be replaced

- A temporary fix or “band aid” approach is to hold it in place with duct tape

Preventative Maintenance:

- Try to avoid over stretching and stressing the valve